why not using a dsp with a real software? i think it would be a more semiprofessional solution / finaly more accuracy and easier to handle less headage better results / rcnc dsp control i can recomand / richauto depend what you want but a clever solution / not cheap but efective

@CNCTECHNICAL

What exactly is not “real software” in your opinion?

mach3 or nc / and all the other nice options

@CNCTECHNICAL

Mach3 works for a lot of people.

because they havent seen the sunny site of milling

@Paul_Frederick I was just parroting a linux wiki page I came across…

http://wiki.linuxcnc.org/cgi-bin/wiki.pl?TB6560

and much like a parrot, I got some of it wrong…lol Says the cap change will get you 100 times more “frqency” (frequency) 400khz…

@Mat_Helm

The cap they’re talking about is the PWM oscillator. Decreasing the value increases the chopping speed of the drive. The drive is not going to run so fast that increasing that speed is going to help any. What will happen is the drive will run hotter though because the duty cycle of the drive will be increased.

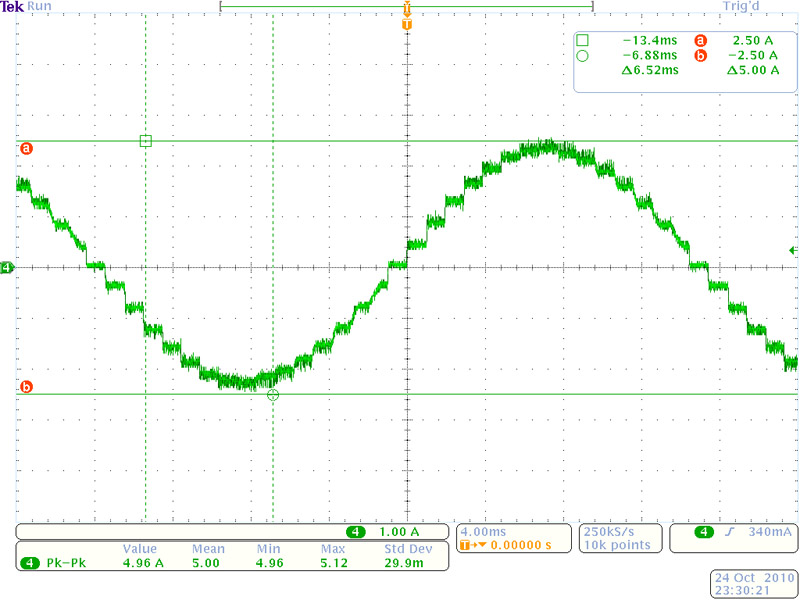

More little squigglies in a waveform like this isn’t going to translate into any performance improvement

The gap between the time scales is just too wide. I can see what they’re driving at but I think it is a mirage. What I’m saying is the big wave (step phase) is never going to get so short that the length of those little waves (PWM oscillation) is going to matter. Your stepper motor will be current starved and stalled out long before then in the real world.

TB6560s have built in diodes so I don’t even know why the imported drives have external diodes on them. Well, I’ve my suspicions. If they are right then those diodes are not really doing anything at all. Changing them out for “better” diodes isn’t going to matter in that case either.

My homemade drives have no external diodes at all and they seem to run OK to me. I don’t know what else to say about that. Leave well enough alone?

The big stinker to me with the imported drives is the current sensing resistors. I know enough about TB6560s to know that those parts cannot be picked at random and peak performance be had. Those resistors have to be selected for the motors that are to be driven.

Anything less than an optimal pairing there will lead to less than optimal performance. No amount of playing with the digital torque control lines is going to change that either.