#OXSpindleDriver

An update on my spindle controller testing since I returned from vacation.

Here is a synopsis of the recent testing.

Created

… The schematic of the controller is complete and shared.

Verified:

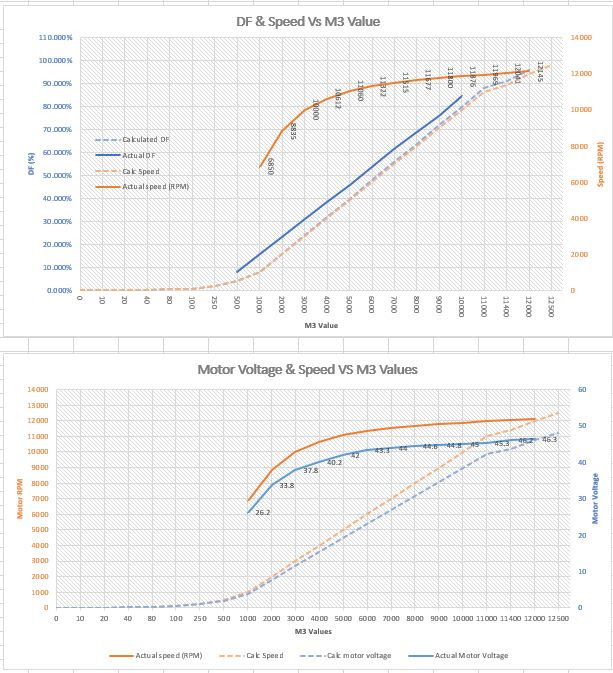

… The TinyG creates a PWM signal from M3 Svalues that are linear and impressively matches the calculated values.

… The TinyG PWM signal properly drives the opto-coupler in the controller

… The actual operation of the controller closely matches the schematic

Fixed

… The previous problem I had with the motor stopping at >95% DF was caused by the TinyG not outputting at values that are close to 500 rpm of the p1csh setting.

… My motor runs approx 12,000 rpm so I set p1csh to 13,000 and I can get a full 100% DF from the TinyG. My phase ccw settings are at 0 and 1.

Discovered

…The motor driver is not operating as I expected. Example: at 50% DF and with the PWM verified as correct at the drivers gate the motor is outputting 43 vdc, almost twice its correct value. This means that the range of control is from 26 vdc to 48 vdc about 1/2 its expected range. Therefore the speed is offset by almost 6x what it should be.

… No idea yet what the cause is so testing continues.

Questions

Not sure I still understand the phase settings p1cp(x). Apparently others are confused since I found a lot of discussion in various searches none of which provided a clear explanation of how they are used.

I gather that these values are the allowable low and high DF values that the TinyG will use when creating a PWM signal. Example: .2 and .9 settings will result in PWM values only between 20% and 90%. I also gather that the PWM will be linear-ized between these values? Correct…No? I did not test this theory.

More

More detailed content, schematics, pictures and test plans are here:

I am not using this to control a laser (although I am working PWM improvements on my laser also in a different forum), I am using this for my OX 400W spindle.

I am not using this to control a laser (although I am working PWM improvements on my laser also in a different forum), I am using this for my OX 400W spindle.