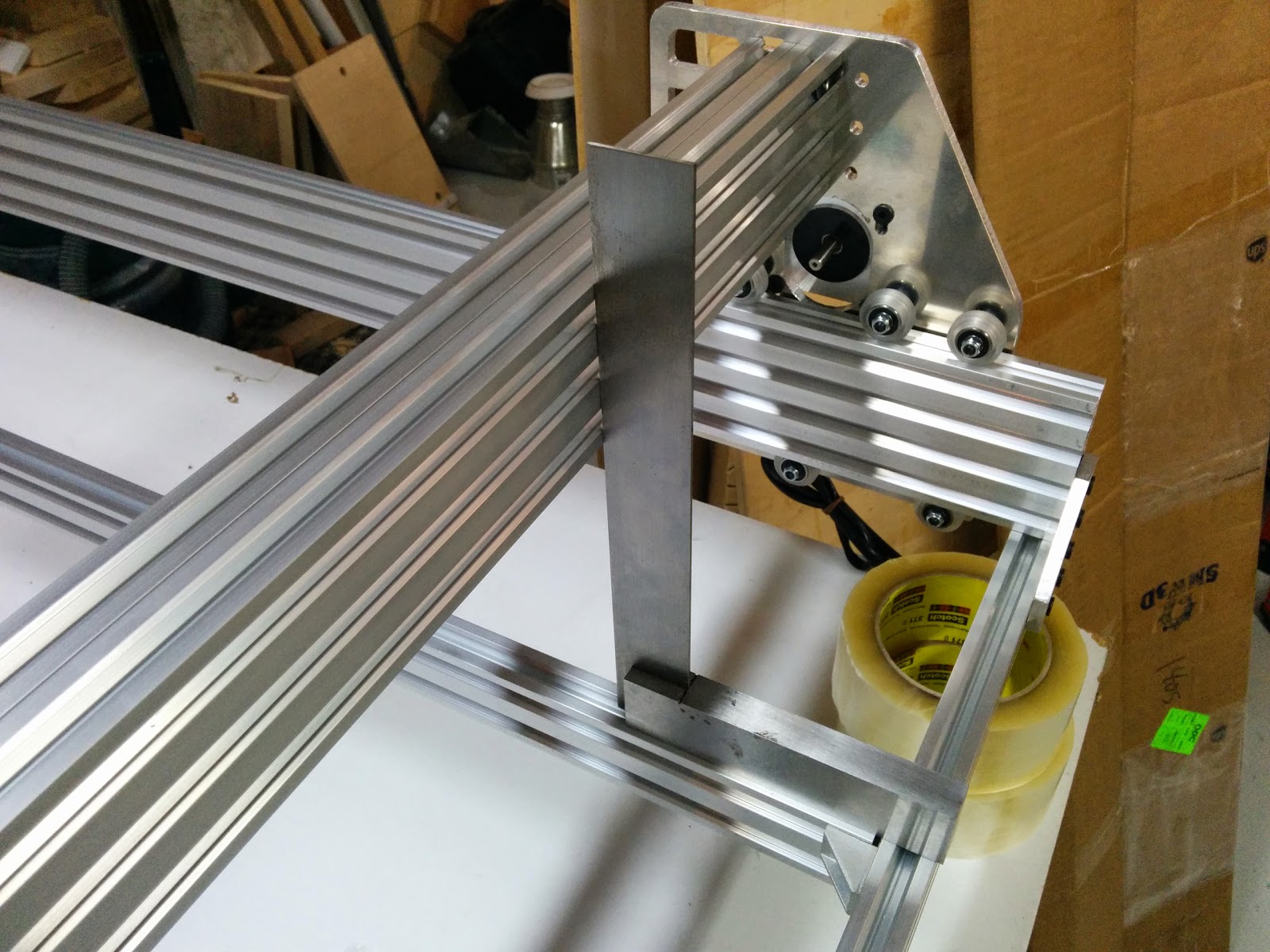

@dhylands Some pictures says more than a thousand of words.

Level by clamping a 3mm straight bar in the ER chuck and jogging Z axis up and down until indicator needle keeps static.

@dhylands Some pictures says more than a thousand of words.

Level by clamping a 3mm straight bar in the ER chuck and jogging Z axis up and down until indicator needle keeps static.

If you have a small square, using that against the round bar and the table and shining a flashlight behind it will indicate that its square to the table.

In theory, the bar could be pefectly parallel to the Z axis (so you’d see no deflection on your indicator) and still not be square to the table.

I think It has to be square in reference to X and Y V-Slots, how it does?, I don’t know.

It might is not possible compare because V-slots surfaces are not completly flat to use as reference.

Making the Z axis perpendicular to the Y axis can be done by twisting the X axis.

(First image from this page: http://blog.davehylands.com/2015/03/ox-build-part-2.html )

That photo shows making it square, which is a good start, but other things could make the actual spindle not be square even though this part is square