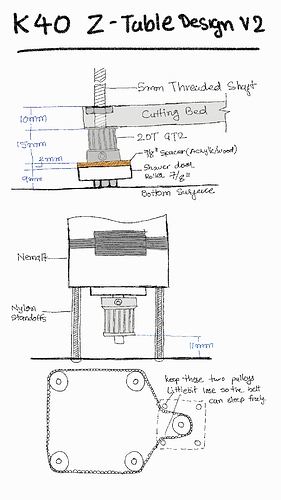

Here we go guys. Z-Table design v2. Only about $25 !!!

If ordered every thing from china and if you are ready to wait:

5 x GT2 20T pulley = $5

1 x GT2 Timing Belt = $5 (5 feet cut to length- more that what we need)

1 x Nema 17 = $9

This one I got from HomeDepot.com not sure if available everywhere or not, but will spend some more time looking for alternative.

4 x 7/8" Shower door rollers = $5

Total = $24 and lets say if we order everything form within the country may be $40-50 depending on where you are.

Looks great. Now I understand the way it will raise/lower all 4 corners at same time. I am curious (and have been since the last design), what is the purpose of the shower roller?

@Yuusuf_Sallahuddin_Y Glad you asked. But I hope I can put that in words after 4 IPA…  . If you look at its design, its 100% perfect for our application and its cheap! The center part can be fixed to the bottom plate with provided bolt. Surrounding plastic wheel/roller spins free that can be attached to our pulley and we can achieve the movement we need for our Z Table to work. Same size bearing is 1. more expensive and 2. center need to be raised from bottom plate to let outer part spin free.

. If you look at its design, its 100% perfect for our application and its cheap! The center part can be fixed to the bottom plate with provided bolt. Surrounding plastic wheel/roller spins free that can be attached to our pulley and we can achieve the movement we need for our Z Table to work. Same size bearing is 1. more expensive and 2. center need to be raised from bottom plate to let outer part spin free.

I hope I made some sense. Again cheap and easy available at local hardware store are two key things I look for in any Mod.

@ChiRag_Chaudhari Yeah that definitely makes sense. I thought it was something similar to that. It’s a really great & simple design. I love how it works & would love to integrate into my conveyor-table idea. Will give me focal-length precision control of the height (for when cutting different thicknesses of leather) & also allow me to do larger pieces in one sheet (minimising waste leather; as I usually end up with near-useless scraps of leather).

So is the 7/8" spacer (acrylic/wood) glued to the shower door roller so that the 20T GT2 Pulley can be stuck to it too?

I have a thought that we could possibly reduce the overall height by removing the 20T GT2 pulley & integrating it into the 7/8" spacer. Could cut a hexagon in the centre of the 7/8" spacer-pulley-combo to put a nut (like what you have at the top) & spot weld it to the 5mm threaded shaft?

How do you prevent it from locking up when running into the ends of the threaded rod?

This looks great. I could easily adapt it to just us a hand crank if I wanted to also…

@Paul_de_Groot well for that just like X and Y axes we have to put optical End switch for Y axes. Edit: Sorry not Y but Z axes.

@ChiRag_Chaudhari I think you mean for Z-axis, not Y.

Or we could just be sure to not make it go too far. I don’t have any end switches for my x & y axes however I just make sure not to go past 300mm on the x-axis & 228mm on the y-axis.

Although, end switches would be ideal to prevent it going too far, as when mine did (while I was testing what is too far) it vibrated all the mirrors out of alignment.

@Gee_Willikers That’s great, but no fun! Always more fun to design & build your own stuff (& usually more expensive in my own experience).

@Yuusuf_Sallahuddin_Y I meant to build my own, but I did some work for my day job and my boss said “…company credit card… buy what you need to facilitate the production of…” So I bought some accessories.

@Gee_Willikers That’s awesome. I need a boss like that haha.

@Gee_Willikers I have spent so much money making something that already exist but at higher prices, so many times that it’s just ridiculous. But the end result is just so awesome and helps many people spend few bucks and get decent results.

Of course that Z Table may just work out of the box, but since I am involved in a little bit of manufacturing, when I see something that can be built for less than half the cost, I go for it. I get hell of a kik out of it. LOL.

@Yuusuf_Sallahuddin_Y “So is the 7/8” spacer (acrylic/wood) glued to the shower door roller so that the 20T GT2 Pulley can be stuck to it too?"

That is exactly the plan Yussuf. The center part of the pulley that stay stationary is 15mm in Diameter and then there is about 3mm plastic roller part that spins free around it which we can be used to make this idea work. However if we user bigger pulley we can eliminate spacer and save 2-3mm. But since I have 6 of the 20T GT2 pulleys lying around I decided to go with them.

If somehow we can cut the groves/teeth on or around the shower door roller OMG, that will reduce the height by another 15mm. But we must save the belt from coming off while turning the pulley from top or bottom.

@ChiRag_Chaudhari I did do a test cutting the 40T on 3mm MDF & I don’t like it. The results are not clean because of scorching. Maybe it is possible to create better pulleys with more air-pressure on air-assist, however I am unsure. Or possibly different material (acrylic maybe) might give better results.

@Yuusuf_Sallahuddin_Y You are absolutely right. You know what next couple of weeks Im going to be so busy, but I have to go visit University Fab Lab and use their Epilog Laser to try cut some 30T Pulleys on Acrylic. That machine is a beast. It does so amazing job. After all its 20K machine.

@ChiRag_Chaudhari I am not sure if we have something like that here, but what is a FabLab? Do you get to use their equipment for free or you have to be a student or you pay some fees?

How do you join the timing belt to make a loop? I have a simular setup as my Z bed for 3d printer and I had to buy a looped timing belt. If it skips you will lose the level of the bed and worse get it to get stuck…

@Yuusuf_Sallahuddin_Y FabLab is like Maker Lab except there is no membership and its almost free to use. They charge $1 for 5 minutes of use of laser cutter, $$/gram for 3D printing. Plus they have embroidery machines, vinyl cutters and many more small equipments. Also they teach you to program arduino and many different things. Pretty awesome place to hangout.

@Imko_Beckhoven_van Good catch. But I found out that they do sell 6ft closed loop 2GT belts. I think they are called 1524mm 2GT closed loop.

. If you look at its design, its 100% perfect for our application and its cheap! The center part can be fixed to the bottom plate with provided bolt. Surrounding plastic wheel/roller spins free that can be attached to our pulley and we can achieve the movement we need for our Z Table to work. Same size bearing is 1. more expensive and 2. center need to be raised from bottom plate to let outer part spin free.

. If you look at its design, its 100% perfect for our application and its cheap! The center part can be fixed to the bottom plate with provided bolt. Surrounding plastic wheel/roller spins free that can be attached to our pulley and we can achieve the movement we need for our Z Table to work. Same size bearing is 1. more expensive and 2. center need to be raised from bottom plate to let outer part spin free.