Is variable speed lasing still in LaserWeb? It looks like constant speed results in the picture. Fast whites should help, I would think. That is assuming he can do variable speed movements.

@K1111 I just took a closer look and I think the only difference may be that mine is on 1.23 instead of 2.4. I’ll have to give it a closer look tomorrow after work and then try changing it to 2.4 to try and mimic yours. I’ll double check the wires to the shifter then to the PSU as well. Thank you for your input, I’ll be sure to update on here tomorrow afternoon.

Also note the version # of your azteeg board

There were some differences in the wiring

Alex is correct. On your board .26 looks to be the same spot as my 2.4. If you’re running two pins your board is not set up the same. The way I have mine done negates the need for the m3/m5 fire pin.

@K1111 @Alex_Krause ah, I see. Would it be worth trying to change it to .26? Here’s another pic of the other pins.

I’d try dropping the blue wire. You’d need to change your PWM to .26 and delete the bit about the fire pin. Of course save it in case you have to revert. So in the end you’ll only have three wires going to your shifter to the PSU.

@Florentino_Villalpan I’ve been up for pushing 19 hours now and have to work a 13 hour shift tomorrow if I don’t respond till Wednesday morning please don’t get discouraged we will figure this out as a community but I’m crashing out

@Alex_Krause no problem at all, get some rest. Thank you for all your help and encouragement thus far. I’ll do some testing tomorrow and update on this post.

im testing a similar configuration for wood photo engraving, the problem is that the material have a narrow treshold from white to black, it seems too much finetuning from pwm with CO2 laser due to high power factor, this foto is the best i can done for now:

Photo engraving halftoned

https://lh3.googleusercontent.com/HFdtYhegixRqZnnHEYm0syKgaWCut7XmTz_qxhtt_S3CpfzZCez7y80gSkQgoXo4Ts0l65upwSxkrw=w1366-h768-rw-no

Variable speed should help some where the whites consistently get too dark.

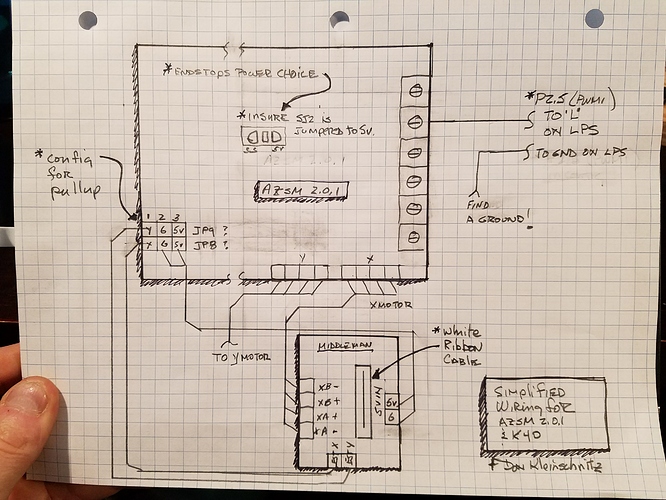

@Florentino_Villalpan , @Alex_Krause , @K1111 very hard for me to tell what is what from the wiring picture so here are some starting recommendations and information.

Attached is a drawing that I created for another member sorry I do not remember whom and how it turned out? This looks similar but not the same?

If you can point me to a schematic for that board, or provide the name and revision) I will be happy to do the same for PWM control on that exact board.

Recommendations:

-

I cannot endorse the use of PWM connected to level shifter connected to “IN” configurations as I am certain it will give unpredictable results, especially engraving. @K1111 is running a level shifter and “L” which works as we know.

-

Recent modelling that I just completed suggests that the period should be set at least at 200us. This finding seems to correlate with members showing successfully engraving.

-

Set the max power in the config to 1. Leave the Pot in place.

-

Mimic @K1111 setup. Try connecting the output of the level shifter to “L” on the laser power supply. The polarity in the config must be set so the signal is low true. If this is the same board as @K1111 then reference her config file. If this works you can leave it alone or I can show you how to get rid of the level shifter.

Other things that will impact engraving:

- The setting of the current regulation pot

- The type of wood, its grain and its moisture content

Attached:

…A drawing for a similar board. (Not sure if this is same as yours)

…A PS connector description. (I think this is your LPS)