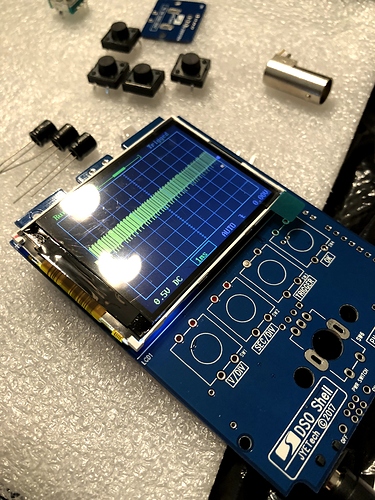

I put most of the oscilloscope together, but I made a couple of errors, which I have to change. I soldered the rotary encoder directly on the board without realizing I had to solder it to another card first, so I had to remove it. In that process the encoder melted and I have to try to replace it. Also, directions were unclear about which side to solder the power switch and I put it on the back side. I attempted to desolder it to put it on the other side, but was unable after several attempts. I’m hoping that it will work fine on the back (it’s a toggle switch). Finally, if you notice on the picture the space to attach the “trigger” button came with some residual solder on one of the connector holes. When I mounted the button, the wire didn’t go all the way through and the button didn’t lay down flush. That caused the plastic cover not to go over the buttons evenly.

I think the instrument still works correctly, but I’m going to try to make the corrections. I ordered another encoder (hoping it’s the correct fit). I’m a little wary about trying to remove the parts I soldered before as it destroyed the encoder and I was unsuccessful with the power switch. I may just try to replace the encoder and try using it without the cover. Making sure the right part is being put in the right space was challenging for a man with my eyesight. I will likely need the scope to adequately diagnose electrical and wiring issues of my machine, so I’m very grateful for the heads up from Paul Fredrick for suggesting it. It’s a good value and many ppl must be buying them b/c so many people are selling them on eBay. Fortunately, the link Fred sent was a bargain.

I’m not going to get the 220v outlet installed until this weekend at the earliest. That’s the earliest time Tim can install it. So, my spindle won’t be connected until next week. I did connect the ballscrews to the gantry and tried moving the axes. It moved fine in one direction, but not in the other. I have to recheck the wiring to see if that was the problem. I was shown by a visitor at the Makerspace the correct way to solder those aviation connectors and I think the ones I have connecting the motors might be causing the problems. I’m going to go in today and look at them.

I thought I told you not to make any mistakes. Board rework is the worst pitfall when it comes to assembling printed circuit boards. So you have to avoid it at all costs. I used to bench solder at a board assembly house so I have a bit of experience when it comes to assembling electronics. One day I was sitting there working and I said to one of my coworkers, “After all we do on these boards when we’re done they’re brand new.” Which considering we worked on runs sometimes for weeks at a time until way past when we were sick of it is a bizarre thought. By then the stuff was pretty old to us. But you still have to keep it in mind. You’re trying to make something perfect and brand new.

@Paul_Frederick Yes, I’ve learned from my least favorite institution…the one of hard knocks.

I have to get some de-soldering wick…so much for perfect and brand new…Right now I’d settle for functional and operative. But, it keeps me learning.

@George_Allen I guess that’s how we all learn? I’ve lifted plenty of solder pads in my day. Enough that I try to avoid being in the position to do it again. When you do rework clean as you go. Try to get back to square one as best as possible. Don’t dig yourself in deeper along the way. One thing I’m fond of saying is there are only three rules to soldering. Clean, clean, clean! Then when people say but that’s just one rule I explain no you have to clean before you solder, you have to clean while you solder (wipe your solder tip) and you have to clean after you’ve gotten done soldering. Otherwise you run into process failures. I’ll prep a board with solvent and clean leads before I even start soldering. Even new parts. Bright and shiny comes from bright and shiny. Especially all of these crap ass lead free solder dipped parts. I hit them with some fine steel wool. But you do have to take care with steel wool particles. I have Scotchbrite but I don’t like how it works nearly as much as good old plain steel wool. When I worked bench soldering they taught me all about flux brushes. How to cut them down so they work better, just how to use them the best. There’s technique involved. I couldn’t begin to estimate how many hours I’ve spent with a flux brush in my hand. Lots. Though we never did use them to spread flux around with. Just to clean flux off stuff.

I watched one YouTube video once where a guy was having all kinds of trouble soldering a board. Then some time after he finished he remembered it was the sample that he was handing around to people to check out. So it had finger oil all over it. The lesson there is even if you can’t see contaminants they can still affect solder jobs. Or there’s no such thing as working too clean when you’re soldering. Things being clean will never adversely affect your soldering.

@Paul_Frederick I just found resistor #4. I don’t know how I saw that tiny thing, but I tested it and sure enough, it was there. So, that’s one problem solved

@George_Allen soldering wick is OK, but I’ve found a desoldering pump to be far more effective. And a pair of multi-lens close up glasses

(I’m blind with age, too and tiny 8mm SMD components give me the shizz)

@Paul_Frederick I just now got to some other parts of your comments. Yes! That made the difference with my recent soldering. I had seen a tutorial on keeping the soldering iron clean (You may have even done it), that combined with the other person who re-soldered my spindle helped me see the difference. As he soldered the wire to the jack you could actually see the connection shine bright. Also, keeping the tip moist and wiping it (shaking off the excess solder when tinning it. It made the whole process a lot less of a problem. It was a bit of an “ah ha “ moment for me. Two big ones: figuring how to properly use those crimping tools and properly learning how to solder have been big steps forward for me. I think my soldering issues contributed to some of the issues I had with my Ox. Much later I likely intend on converting my Ox to a laser cutter (if, by then, I can afford a powerful enough laser tube and power supply).

@George_Allen contamination is by far the leading cause of solder issues. So a moment spent cleaning prior to making a solder connection pays dividends. Even things that look clean will always solder better with a little touch up done on them. A scuff with a bit of fine sandpaper or a bit of plain fine steel wool. Maybe hit stuff with a solvent? Isopropyl alcohol is a popular choice. A lot of oils and oxides are not visible to the naked eye. Things can appear to be clean but not be. Solder will not flow right when there’s the least bit of contamination. I’m generally not Mr. Clean myself. But when I solder I try to be. Because I know it’ll make things go easier for me.

I just got some more crimping tools in a toolbox of telephone tech’s tools that I picked up at a flea market. Not that I needed any of the junk but I have a sickness called toolitus. Sometimes when I see tools I have an uncontrollable urge to possess them. Especially when they’re cheap. I got that whole box of junk for $10

Use one of those steel scouring pads - just push your iron into it and it comes out shiny.

Flux and wetting are the key, as is a good quality lead solder. If it ‘clumps’, throw it away. I use .8mm for fine work, 1.2mm for general use. A good British or US brand, not the crappy Asian solders (except Japanese - good stuff!)

https://plus.google.com/photos/…