I shared this post with Chilipeppr private group and not the community by mistake, sharing now.

Originally shared by Sebastian Szafran

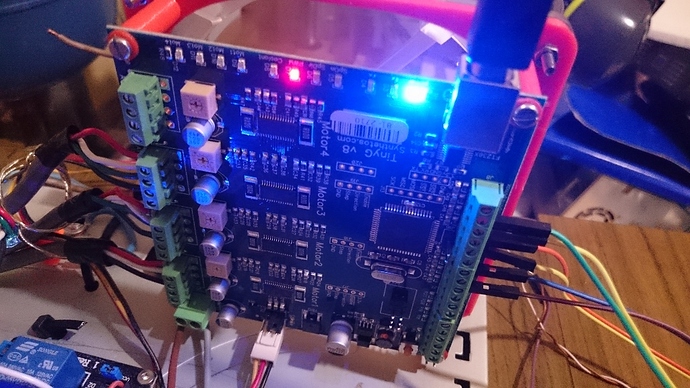

I finally connected the TinyG v.8 board today and made a first move.

My setup is:

- CNC 3040 with NC limit switches for X (wired to Xmin), Y (wired to Ymin) and Z (wired to Zmax)

- switches configured as Homing+Limit on the TinyG

- NO probe connected to Zmin

- 120mm 12V PC fan connected to TinyG and continuously cooling the bottom part of the TinyG board

- current limiting pots set half way (~50%)

- switches and probe are running 5V and I used optocouplers to conenct them to TinyG

- Vmot is 30V, I ordered 24V (recommended) power supply on eBay

First tests:

Homing works fine with my NC limit switches, although the cycle is a little different than in TinyG2.

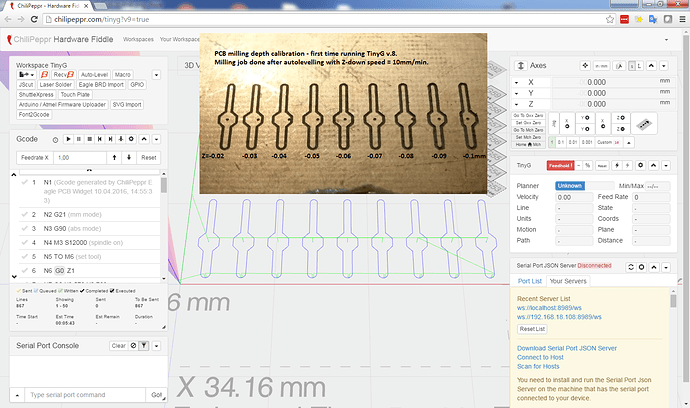

Probing… after my experience with G2, no problems here so far. I used 36 probe points to probe the test job from the picture below with having no issue here.

First job - this simple job contains nine identical elements, a simple pin with two traces 16 mils facing up and 24mils facing down. The only difference is Z-depth, starting Z=-0.02mm down (most left) to Z=-0.1mm (most right) with -0.01 step down. I want to see what milling depth is best for my machine setup.

The problem:

After running the milling job I found the first occurence already fine from the depth point of view (will probably try even a bit higher next time), but there are some issues:

- elements are placed not exactly as they should be

- last two elements have some shape issues

- drill locations are not correct

- the width of traces should decrease going left to right, as we go deeper with milling, but this is not

Have anyone met similar issues?