@dougl @mcdanlj

A while back I mentioned I thought I might be fighting multiple demons. I think I may have identified some of them.

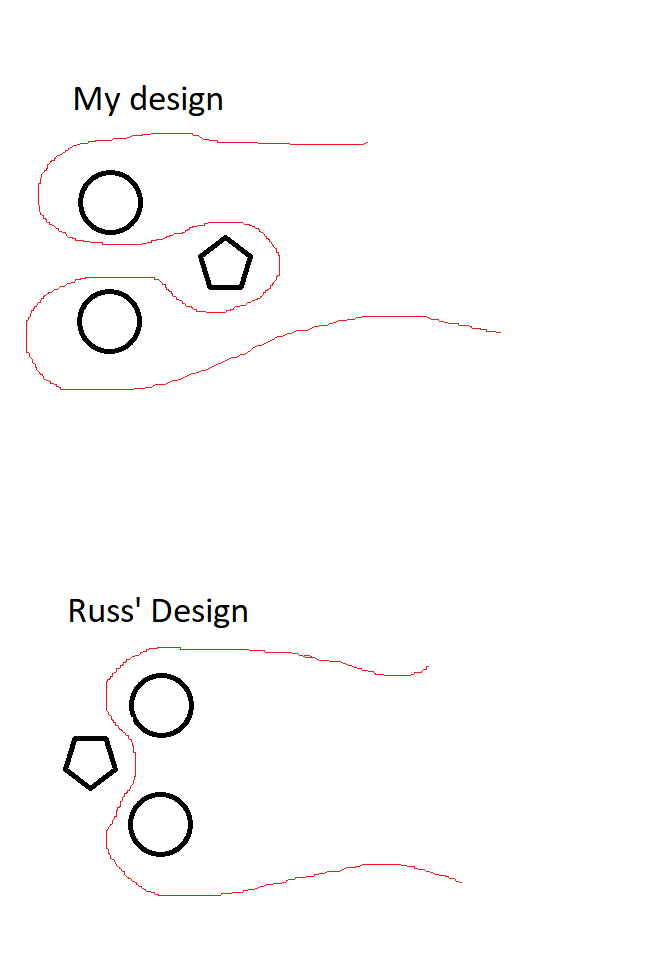

Firstly, I understand that the teeth and pattern spacing didn’t line up perfectly. I gave a number of 6mm, which is my best guess (I think it was difficult to identify which spacing to measure because there are actually overlapping patterns). Lets say it was 8mm or 4 teeth, that would be in sync with the pulley rotation and fall in line very will with Russ’ explanation.

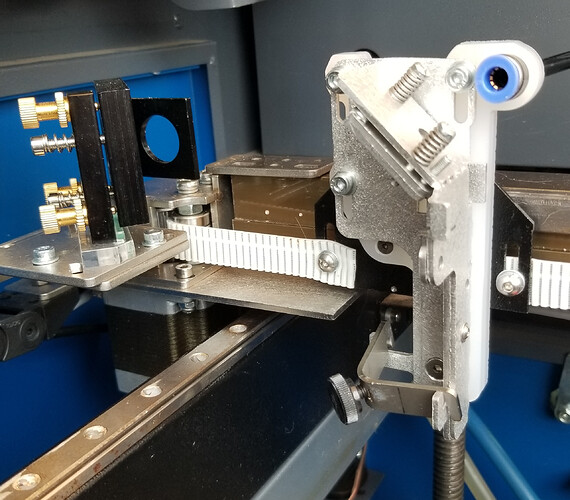

That being said I switched the X-Axis pulley to a 36 tooth pulley and seem to have some better looking burns. Thanks @dougl , I think you found one of the harder to identify issues. There are still two other issues that have been overlapping with the pulley issue the entire time.

Oddity 1 (solved):

Possible glue trowel marks / weirdness in between layers of plywood:

I have overcome these lines by avoiding burning right in between layers of the plywood.

Oddity 2:

Non linear laser power:

There are 3 burns done in this image. From left to right the acceleration values of the x axis were increased by 500mm/sec2. The left is 1000mm/sec2/ middle is 1500mm/sec2 and right is 2000mm/sec2. As you can see, the 1000mm/sec2 burn (the burn with the most changes in speed) is very reminiscent of the “curtain” effect, but looks close to a gradient. It should not be a gradient, this should all be burned to the same extent, but with the speed changes, the controller is attempting to adjust power, but is not doing well. This leads to some stripes/curtain looking effects. it gets better in the second burn, and a little better in the last burn. That is because the head speed is more constant as it truly reaches the desired speed sooner due to the higher acceleration values.

I then did a burn with a very large overscan to see if the burn remained consistent without power level changes:

This turned out really good. All of the speed changes occur outside of the burn area, hence no power level changes during the burn.

So the question is, are there any good ideas on how to make the laser power more linear? I know that FluidNC has the speed mapping options, but are there any good ideas about how to find the numbers to set them at? Is there something I can do with the potentiometer that can help here?

Edit: fixed grammar and spelling