I am trying to embed an endstop in the hotend mount so that it can be used as a Z probe or just to prevent catastrophic crashes of the nozzle to bed. I am not sure I have this right but from my understanding the usual endstop setup is to use the NC configuration and the circuit being broken when the lever is pressed. For this particular setup I need to have the NC with the pressed lever. This shouldn’t be hard to implement right?

My design includes an easy replaceable hotend mount that can rotate around a pivot axis when the nozzle is forced into the bed surface. The mount has an arm that normally presses against an endstop, which will disengage when the nozzle will be forced into the bed.

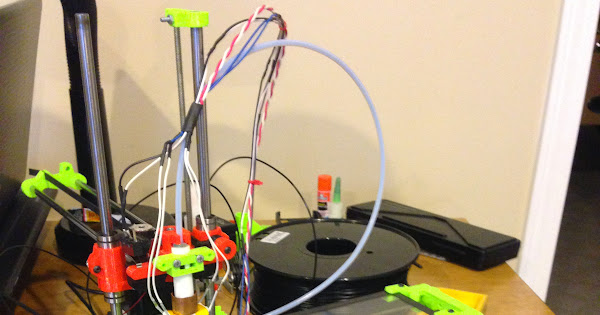

Rough sketch below:

Edit: n case it isn’t clear my question is how to solder the endstop so that I get the results I am for and how to setup this particular configuration in Marlin?

What kind of bed do you have? You might be better off using the hotend as the probe itself if you have an aluminum bed. My Smartrap had this setup and it made for inconsistent prints.

@Griffin_Paquette The bed is glass on top. What was to blame in your setup? The microswitch? The tension spring required to keep the lever pressed? I don’t suppose you have any pic of that setup?.. I saw this kind of configuration on deltas (ex: https://youtu.be/e119OXzkk7s) and recently Voron x carriage has an endstop embedded quite similarly (https://youtu.be/ypGzWQ7K4LA)

The issue was the play in the lever for the switch. You might want to try using a super inexpensive mechanical push switch like @Thomas_Sanladerer uses on his Delta endstops. They have no real play.

@Griffin_Paquette

Hard to see in the picture. Nevertheless I am not using the lever (I just didn’t know how to call the “button” left when you take the lever off). In my sketch the switches are the kind you find in mouses and which i have a few.Are you maybe talking about the internal levers of the switch?

@Griffin_Paquette

I thought of using these kind of push-button microswitches that Joseph Prusa also used in a youtube video about bed leveling but as long as you take away the lever from any microswitch you end up basically with a similar mechanism.

The @ATOM_3D_PRINTER does it pretty well - it uses a hard, mechanical shoulder to register the hotend mount, alongside an adjustable switch to trigger when the hotend touches down. Pretty much exactly what you want!

The mechanism should be visible in the review https://youtu.be/ygHrhfxhx38, if it’s not clear from that i can take a few pictures tomorrow.

Thanks @Thomas_Sanladerer It’s quite clear that it does the same thing I am after. From the video I see that the mechanical metal shoulder raises up, depressing (?) the endstop button but I can’t but infer from what I see. I’m interested in some more close-up pictures as I want to implement about the same thing.

Edit: I am also interested in what spring setup does the Atom use to get the hotend back to its position…

Ok, I’ve watched a few Atom2.0 videos (https://is.gd/4z5Fqx, https://is.gd/RwlsS7), the microswitch seems to be normally presses by virtues of a spring loaded bolt that pierces the effector plate and protrudes downwards parallel with the hotend:

I wonder if there is a manual somewhere of the Atom2.0 assembly…

Ok, it was easy to find actually, it just didn’t come in the first results the way I searched: https://is.gd/rg43QK

The spring only serves to pretension the bolt, keeping it from coming loose, the actual springiness of the hotend assembly come from the sheet metal “upper effector”

@Thomas_Sanladerer Ok, I understand… that might be quite difficult to achieve repetably with plastic parts…n

I think it might be quite possible - the registration to have the hotend at a repeatable position is trivial, and using an actual hinge like you’ve drawn up should make it work with stiff FFF parts as well. Maybe a pair of magnets to hold it down?

@Thomas_Sanladerer Yeah, now trying to think something for holding down… Magnets would ensure coming back to initial position every time but still a spring must bring back the rotated assembly to magnets range. That might be achievable with springs alone.

Does Atom 2.0 have proprietary software? How should I do with Marlin (and also which legs to solder to get the NC) about having the NC microswitch when pressed and to trigger when depressed?

The Atom uses standard Marlin, which can be downloaded right on their page (i’ll leave that Google query to you, but it’s, like super easy to find). Microswitches can do both NC and NO, while the 6mm pushbuttons only do NO. Use a multimeter to figure them out.

@Thomas_Sanladerer I can find it if it’s not proprietary. I’ll have to refine my skills with electronic equipment though … to be able to work out the “NC when pressed” requirement.