Hi all.

I am a newbie trying to get my new K40 set up. Not even managed to get a laser beam yet. There’s at least one problem with it and I’m hoping one of you lovely people can advise what part of it I should try replacing first.

It powers up and the light on the board illuminates. However with the laser switched on I get no reading on the ammeter (analogue, pre-installed). The test switch on the cover does nothing. I believe the current regulator does something - if I depress the test switch on the PSU I can get a reaction around the laser tube only if the current is cranked up to max, though not one I like. There is slight arcing from the tube to the case near the anode and clearly a strong stray electrical charge. The water in the tubes ‘twitches’ (if pump not active) and I noticed my trousers being attracted the the water reservoir! I am guessing that there is either a fault in the tube shorting into the water (arcing), or the PSU/controls are not delivering power to the tube correctly (inactive ammeter). But that’s where Its all getting beyond my knowhow.

What would people try fixing/replacing first? Laser, PSU or something else?

Thanks

(There’s no flow switch in the system)

For starters track the wires from both ends of the tube and see where they go.

First check the wires @TwelveFoot suggests.

The cathode wire should connect to the LPS L-. This is generally located on the far left connection of the LPS in the same connector with the AC power.

What light on what board are you referring to?

[quote=“Kitch, post:1, topic:84979”]

The test switch on the cover does nothing. I believe the current regulator does something -

[/quote]

When you do this is the 'LASER SWITCH" ON?

Do you mean it arc’s violently? Can you post a video?

Generally, a LPS will arc when the tube is not providing a load. This most often is a bad tube. Tubes can go bad from leaks, or tube damage. Carefully inspect the tube for cracks or leaks.

Please post a picture of your LPS showing the input connections.

Have you contacted the seller?

First - thank you for responses.

Answers to a few Qs.

The light I referred to is the one marked ‘power” on the circuit board between connector blocks, as visible in the attached photo.

The arcing is barely visible but quite audible, I would struggle to capture it in a photo or video.

The actions I describe are with the laser switch on. The laser switch and the test switch can be tested without any power and function perfectly as switches.

Not contacted the seller yet. I got the impression this doesn’t always get as helpful response as I’m getting here and I trying to learn as much as can before I do so.

Another test I have tried is attaching the tube wires to a length of bamboo skewer to see if it will arc along that. It does so very nicely when the internal test switch is depressed, though nothing when the switches on the top of the unit are used. I guess that the wires can deliver a healthy current to the tube.

I might muster the courage to try to video some of this tomorrow but right now, given the charge I felt from the water tank, I’m not sure powering up is entirely sensible.

Your using 100% power when you push the Test button on the LPS itself and the other buttons the power level is set the the Potentiometer(POT) knob just to the right of the Ampere meter. This might be why you are seeing a difference in how the arcing is different.

BTW, the wire from the left end of the tube should run to your Ampere meter to one of its terminals and the other terminal will have a shorter length of wire running down to the L- connection on the LPS.

It does sound like you have a cracked tube if you see water hoses jumping. But you should NEVER run the laser without water flowing. That water is a coolant and it must flow to cool parts of the tube otherwise the tube will crack and break.

Many thanks for the advice. Tube ordered. Fingers crossed.

And just so I dont look like a complete numpty,(hopefully), the laser was activated for less than a quarter of a second without the water flowing, just as a momentary testing manoeuvre.

Are you using something other than distilled water?

Think I’m ok now folks. Removed the tube and a close inspection reveals that there is a leak internally an some water has entered the gas chamber part of the tube. Thank you all for your guidance.

same story here, i has bougt also a new K40 and i has testing the machine on 20 % power for a veri small time without water cooling, resulting in a not working tube now, i see water in the discharge tube

i new istube ordered now

i am totaly new with CO2 lasers, so are there more inportant things that i should to know?

sorry for me englisch

greetings from Belgium

@Kitch be advised that the LPS is lethal [20,000Volts]. I would not advise disconnecting it and doing any testing with it live and not connected to the tube.

@wilver there is lots of K40 information on this forum start with the links up on the ribbon at the top of this forum.

Here is some more info. https://donsthings.blogspot.com/

The New to K40: Start Here post will get you started, and it links to content in the Getting Started with CO2 Lasers categorty. That category is moderated by some of our experts.

Always have water flowing through your tube and without bubbles in the tube before firing the tube for any length of time. People put water flow indicators above their machines just to make sure there’s water flowing and they often get them after they’d broken their tube by not having water flowing for one reason or another and turning on the laser power. ie after learning the hard way.

… and or add a flow sensor into the interlock circuit… that is what WP means water protect

hi there

thanks for the answer

i have a new question

what is the distance between the tube output and the first mirror?

thanks

I can go measure but curious why you want to know.

i bought a new K40 but the tube is broken(transport??) so i has to placing a new tube and i will know the distance(maby that distance is important? )for adjusting the mirrors

thanks Sir

In my machine, the end of the tube is about 1" to the center of the first mirror. That distance is not important.

What is most important is that the laser is parallel to the x-axis of the carriage. Then realign all the optics to that position.

I would mark the current lasers bracket’s mounting position as a starting point.

if the cooling water passes through the tube, should the tube be completely filled with water? with my tube I see that the tube is only filled to half the diameter, I have no air bubbles and the cooling water flows very well

before I control my laser I want to be sure if it is normal that the tube is only filled to half the diameter with water

sorry for this question, i am just started with CO2 lasers

There should be FAR more water in the tube than half way and I would not fire the laser with that setup. Since you are new to the K40 and CO2 lasers I HIGHLY recommend you read all of the K40 Info here( New to K40: Start Here - Getting Started with CO2 Lasers - Maker Forums ) and all of the K40 Quick Help here( K40 Laser Cutter Engraver FAQ and DIY Website | k40.se ).

I could not find on either site the specifics of water filling the tube so here is what I found about “bubbles” in the tube at this site( What are the air bubbles in the CO2 laser tube and what to do to avoid them?-Bunny | XTLASER )

By rotating the laser tube so that the water outlet is the highest point of the cooling loop. This will prevent air bubbles from forming around the cavity of the reflecting mirror.

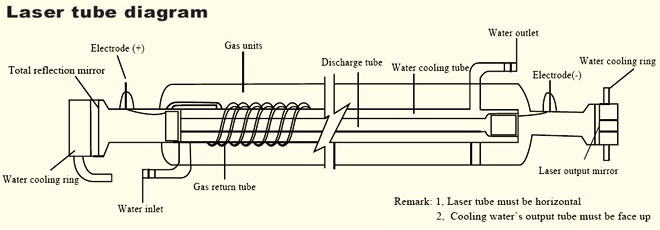

It just dawned on me that you might be seeing water in the outer casing of the laser tube… There should be no water in the outer case of the laser tube. Only the inner tube section:

also seen in this video: