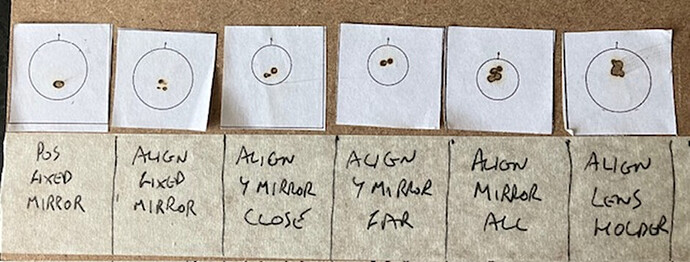

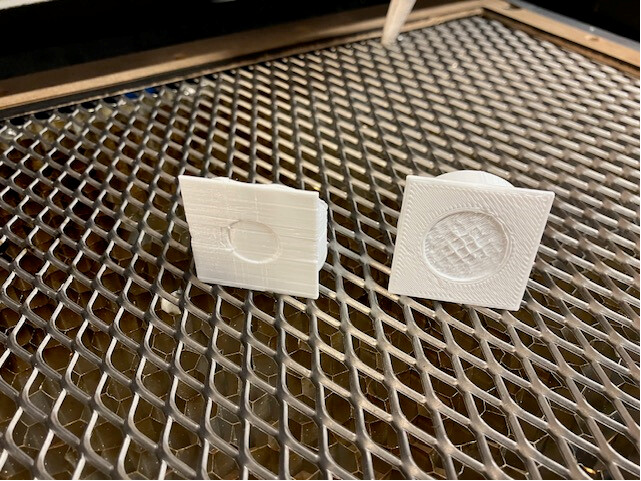

The jigs for both the fixed and Y Axis mirrors and the laser head work well in that I can place the tape on the jigs then slot over the fixed and Y mirrors lens cap or the laser head. It’s a fair point about protecting the mirrors so I have closed off the holes and indented the position of the holes which are now only 0.5mm from where you would place the tape in any case.

Part of the problem of aligning the mirrors is that I need more adjustment of the head both in the vertical and horizontal, so I have printed a head part which includes the drag chain bracket that makes adjustment easier. I sense that I may need to re-align mirrors periodically so making the process easier will pay dividends. But, as if that was not enough, I realised that in homing, my drag chain was fowling the back of the cabinet. This in turn seemed to push the gantry cradle upwards and so may be part of the problem.

Correct position

Pushed upwards

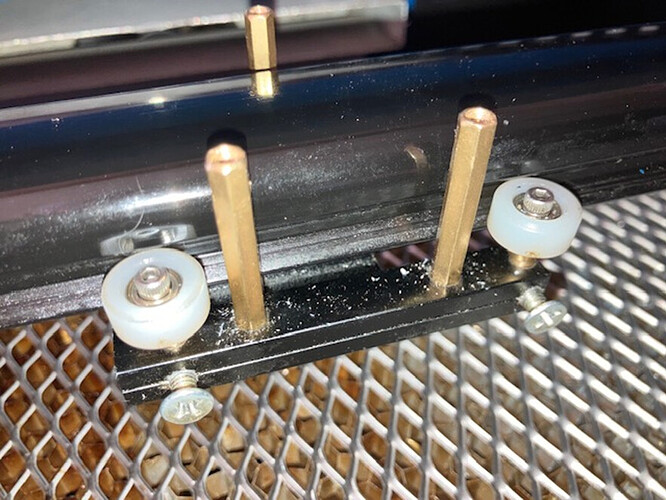

As you can see in the two photos, the cradle can easily be pushed upwards out of the rollers. I tried adjusting the rollers tighter against the gantry, but this only tightens the movement along the gantry so does not work. Although I appreciate there should be no undue pressure on the cradle, and I have fixed the drag chain bracket problem, nevertheless it seems odd that this should happen at all which led me to think that maybe my cradle was incorrectly assembled or missing a part or something else, but I can’t find any posts on this as an issue. Any comments? I certainly don’t have this problem on my printer where the rollers are firm in their guiderails. Anyway, I hope to be able to pull all this together tomorrow and carry out re-alignment testing again. The one good thing about all this is that I am learning a lot about my k40 !!